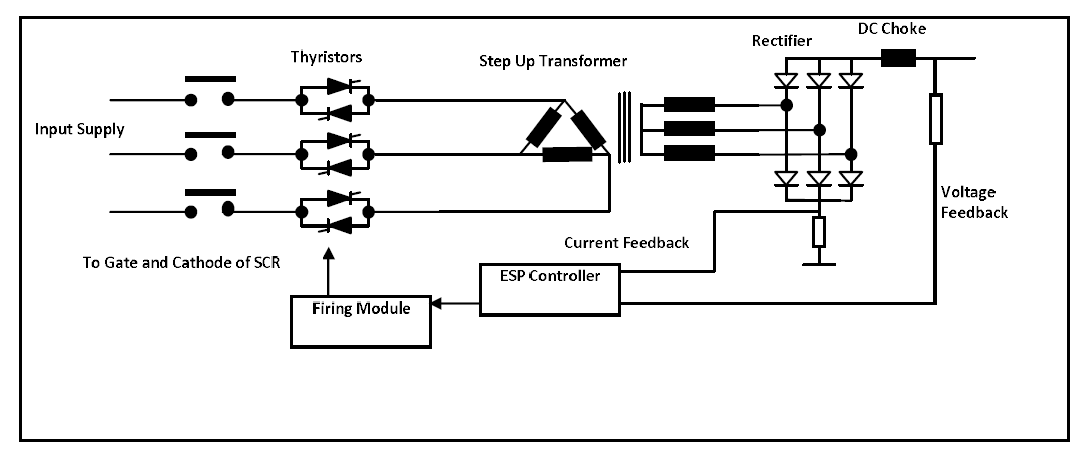

ESP Transformer and control

ESP Transformers for powering electrostatic precipitators (ESP’s) with over 15 years of experience and design for high voltages up to 130 KV and 5000 mA.

- Single Phase 110 V to 240 V and Line Frequency 50/60 HZ

- Three Phase 220V to 415 V and Line Frequency 50/ 60 HZ

- Output DC Voltage up to 135 KV(P) & Current up to 4000 mADC

- Available in Hermetically Sealed Construction

- Available with Conservator Tank Construction

- Oil Natural Air Natural Cooling (ONAN)

- Manufactured from High Quality CRGO and CRNGO Silicon Steel

- Have Exported for Ambient Temperatures As Low As -40*C

- HV Transformer, Rectifier, AC Reactor & Choke Assembly is Lid Mounted for Ease of Maintenance and Repairs.

- Doubly Wound, Cross over Winding with Electrostatic Shield Between Primary and Secondary Windings.

- High Frequency Chock for Surge Protection of Rectifier Diodes

- Conforms to Protection Class IP-65

- Bushing Orientation: Horizontal Or Vertical